Commissioning a newly installed fire suppression system is one of the most important functions. This is to prove the system functions correctly, the system is safe, the documentation set and certificates are complete, and the system is handed over to the client correctly.

The person responsible for commissioning a gaseous fire suppression system will have to go through several key points to ensure the system satisfies the requirements of the relevant standards and ensure the system will suppress a fire in the area it is protecting. The following are the standards to be referred to when commissioning a gaseous suppression system. Depending on the type of extinguishant used:

• SANS 246 – for electronic equipment installations.

• SANS 306 Part 4 – for CO2 systems.

• SANS 369 Part 1 – Electrical actuation of gaseous total flooding extinguishing systems.

• SANS 369 Part 2 – Mechanical actuation of gaseous total flooding and local application extinguishing systems.

• SANS 14520 – Gaseous fire-extinguishing systems – physical properties and system design.

There are two aspects to a gaseous fire suppression system, the electrical part and the mechanical part.

Electrical installation

The fire detection system must meet the basic requirements of SANS 10139, SANS 246 and SANS 369-1

The following points need to be considered:

1. Ensure the appropriate type of the detectors are installed and sufficient to cover the area they are protecting (1 per 50 m² minimum). Ensure the wind speed and flow direction of the air conditioning equipment has been taken into consideration as it influences the quantity of detectors to be used.

2. Ensure that the detectors are installed in coincidence connection, meaning two different detectors have to operate to activate the suppression system. The same applies for the ceiling void and floor void detectors.

3. The gas control unit is located at the entrance of the protected room with a manual switching device to enable mode of operation of the system to be changed from automatic to manual when personnel are entering the protected area.

4. There are visual and audible indications at the gas control unit to show the system status. This should also be provided at every entrance to the protected room. The operation of repeaters must function in conjunction with the main fire control panel to ensure that there is interlinking of the devices.

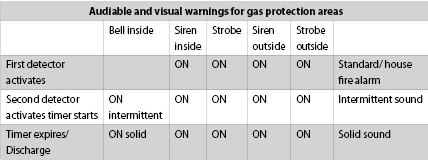

5. Audible and visual warnings are provided for, both inside the protected area and outside the area. The FDIA is promoting uniformity for audible and visual warnings for gas protected areas. Below is an operational philosophy we are asking all contractors to adhere to.

6. A manual release switch or break glass unit to release gas has been provided. The switch should be yellow in colour with operational instructions and signage indicating function and method of operation of the device.

7. If the area is normally occupied when the system is in automatic mode, then a hold switch should be provided to delay the countdown to discharge while the switch is held down. Upon release of the switch and provided the system is still in alarm state, the countdown should start from the beginning.

Electronic areas

8. Electronic areas have to comply with SANS246 and there are guidelines given on which type of detectors are to be used in these electronic equipment installations. The type of detectors will be determined by the category of risk identified. Three categories are mentioned in the standard and they are C – Medium Risk, D – High Risk and E – Critical Risk.

A high-sensitivity smoke detection / aspirating system is the only type of detection recommended for category D and E.

9. For high-risk category D and E rooms, it is a requirement that aspiration detection is installed at the return air grill to sense smoke picked up in the movement of air.

10. The type of detection, wind speed and wind flow direction of the air conditioning equipment influences the quantity of detectors to be used.

All of the above become the responsibility of the commissioning technician to ensure everything is installed as per the SANS requirements and functions correctly.

Mechanical installation

This section includes the cylinders and installation of gas distribution pipe and fittings. The mechanical check should involve the following:

1. Every gas system installation shall be provided with a gas hydraulic calculation which has to be checked by the commissioner.

2. The dimensions of the room should be measured to ensure they are the same as the hydraulic calculations provided.

3. The pipe size and layout is as per the hydraulic design.

4. The pipe fittings used shall be in accordance with the standards and be able to withstand system frictions and pressures.

5. The nozzle size and type is as per the design.

6. There is a dirt trap installed at the end of each pipe so that dust and foreign matter does not impede nozzle orifice.

7. The pipe work and cylinders are securely fixed so that there is no movement during discharge.

8. The gas cylinders are clearly labelled, showing the type of gas, capacity of cylinder, quantity of gas inside, date and approvals.

Room integrity test

9. All cable and other penetrations or openings into the room are adequately sealed to prevent extinguishant gas escaping out of the room.

10. A room integrity test should be carried out to confirm that the extinguishant gas will remain in the room for the required time (10 minutes for clean agent gasses) and a report for the room integrity test included in the documentation.

11. Some rooms will have openings during normal operations, like MCC rooms to allow to air circulation, in such cases dampers will have to be provided for. Aircon shut down units for server rooms need to be interfaced to the suppression system to switch off the aircon during discharge, if they are supplying fresh air to the room but recycling units can be left running and can actually assist in the dispersion and mixing of the extinguishing gas with in the risk area.

12. The type of agent used may necessitate the use of pressure vents, especially if it is an inert gas used as an extinguishant. This is to prevent damage to walls and windows due to increase in pressure within the room, caused by the gas discharge.

All of the above must be either witnessed by, or conducted by, the commissioner.

Documentation

The documentation for a suppression system should include the hydraulic calculations for pipe work, design concentration for the type of gas used, report on room integrity test, certificates and approvals for the system and equipment used. A signed certificate should then be given to the client that verifies the installed system operates correctly in accordance with requirements laid down by the designer and that the commissioner carries liability for the correct operation of the system.

Gas commissioners shall be registered at the SAQCC Fire and carry an identity card of such. We encourage end users to use FDIA registered companies as they have the relevant registrations, training and experience and are committed to working to the required standards.

For comments and enquiries please contact the FDIA on [email protected]

| Email: | [email protected] |

| www: | www.fdia.co.za |

| Articles: | More information and articles about FDIA (Fire Detection Industry Association) |

© Technews Publishing (Pty) Ltd. | All Rights Reserved.