Large open spaces, particularly warehouses, present a very unique set of challenges as far as accurate and timely detection of fire is concerned.

Adherence to the relevant standards becomes a major factor once the limitations placed on design and technology have been considered.

A good example of the various factors involved is the recently-completed project at the SCM distribution centre in Elandsfontein - a large complex of warehouses up to 40 000 square metres in size and with high roof structures of up to 23 metres.

In discussion with all of the relevant parties concerned, the various options were addressed.

Obviously the first option considered was to use normal point type optical or ionisation detectors. The SANS 10139 standard, however, limits the use of point detectors to ceiling/roof heights not greater than 12 metres, and then only under certain circumstances.

The reasons for this are valid in that given stratification and dilution factors, these detectors would not be sensitive enough at roof-height to provide the early warning of an incipient fire required in a large structure.

While point detectors typically operate between 3% and 5% per metre of obscuration, a large fire at ground level would be required to achieve this at a height of 20 metres.

The second option would have been the installation of beam type smoke detectors.

These operate on a similar principle to an intruder detection beam where sufficient smoke should be present to obscure the majority of the infrared signal between the transmitter and receiver units.

While the standards compliance could have been met, the difficulties involved with installing these in this particular environment were that the maximum distance between a transmitter and receiver is 100 m. Both the length and breadth of this building exceeded this and the use of additional units, and therefore cost, and specially manufactured brackets would have been required.

The biggest drawbacks, however, were the fact that a building of this size is subject to sufficient expansion and contraction to cause misalignment of the smoke beams and the sensitivity of beams which typically operate at around 18% metre of obscuration. Once again, this level of sensitivity is not sufficient for early warning in this environment.

From the above we can see that the summary of challenges faced was: height; sufficient sensitivity; ease of installation; and compliance with standards.

The solution that could meet all of the requirements and still offer a cost effective system to the client was an aspirating smoke detection system.

Aspirating systems such as the Vesda units installed differ from normal smoke detectors in that they are active devices that draw air in from the surrounding environments using a pump rather than relying on thermal lift to carry smoke into the detector.

Additionally, the use of a laser for light scattering as opposed to diodes also means that greater and more accurate levels of sensitivity can be achieved.

The onboard software allows for background smoke levels, such as those produced by diesel forklifts can be ignored and only smoke pertinent to an actual activation factored into the calculations.

Contaminants in the air (dust etc) can be filtered out of the sampled air ensuring that the smoke still reaches the detectors and that product life is maximised and life cycle costs reduced.

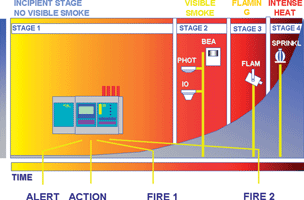

Four alarm levels allow for various response activities to be co-ordinated at the correct time.

The installation went ahead with 22 Vesda Laser Plus units installed in the first 40 000 m² facility and the results were truly impressive.

A test fire created at ground level triggered the detectors in less than 70 seconds, at a roof height of 22 metres.

Not only have the challenges of smoke detection in a large open space been addressed, but also the end-user has a state-of-the-art detection system offering a real level of protection, not merely a 'lip-service' installation.

Dave Boyack can be contacted on +27 (0)11 237 9600 or [email protected].

© Technews Publishing (Pty) Ltd. | All Rights Reserved.