Fire protection systems are some of the most important but often overlooked, undervalued and underestimated parts of complex mining and industrial facilities. In many instances, these systems are treated as afterthoughts in the long design processes that are typical of new greenfield mining developments.

At Sperosens we believe in a different approach. As experts in special risk fire protection, with experience gained over decades in this market, we believe in the application of tried and tested engineering principles in the design of fire protection systems.

Our extensive experience in this field has taught us that fire protection can actually be seen as the hidden engineering discipline. It is a subject on which almost no university engineering faculty in South Africa touches at the undergraduate level, while in fact it encompasses aspects of almost all engineering, as well as other scientific disciplines.

Practicing fire protection as an engineering discipline provides the opportunity to apply various skills possessed by engineers in challenging environments. The design of fire protection systems is guided by various local and international standards which cover various approaches to various fire risks.

As with any other engineering discipline, it is essential that engineers practicing in this field make an effort to understand the various standards, codes and guidelines that apply to it. In most cases, it is necessary to do a proper risk assessment to identify and define the fire risks that may be present in the facility of a client.

Adapt to the specific environment

When designing fire protection systems using the standards as guidelines, it is also important that engineers use their judgement and experience to adapt their design approaches to suit the actual situation on site. This is important, as a seemingly small change to the layout of a plant or mine can have a marked effect on the design of a fire protection system for the area or installation.

Apart from understanding the fire risks and operational concerns of the area in which the fire protection system will operate, the design process that follows requires a very detailed and often iterative design approach, using extensive hydraulic calculations, electrical and instrumentation design, as well as a proper understanding of the engineering principles involved.

As fire suppression systems can be quite extensive, the use of specialised hydraulic calculation software is employed in these designs in order to find an optimised and practicable solution for the client.

A proper understanding of pumps is also important, as many large fire protection systems require the use of pump stations with multiple pumps, all interconnected with an intricate network of piping that may cover the whole facility.

Traditionally, when designing pumping systems for mines or process plants, pumps and pipe networks often only need to be designed for a single duty point, which simplifies the design of these systems.

A fire protection system typically does not have only a single application or duty point, but multiple operational modes in various combinations, resulting in various duty points that need to be accommodated with a single system. Operating all these combinations in a satisfactory manner requires that the pumps and pipe sizes used must be selected carefully to be able to accommodate all these variances.

While taking these challenges into account, it is also necessary to calculate and confirm that the water densities at the various risk areas are met or exceeded when compared to the requirement for that specific risk.

Detection systems design is as important

As a fire protection system is typically a combination of suppression and detection systems, it is just as important to consider the proper design of the detection system. Just as with the suppression, the engineer should understand the challenges of the environment in which the system will operate, as well as the capabilities and limitations of the detection equipment used.

It is of no use that the suppression system is properly designed and installed, and the system does not activate in a satisfactory manner due to some flaw or limitation in the detection system. It is important to follow a complete systems approach, where all the variables need to be considered and combined to form a complete solution that is well engineered and fit for purpose.

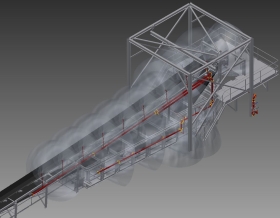

With decades of experience in special risk fire protection, as well as a team of highly qualified and experienced engineers, Sperosens is well placed to provide the complete range of engineering services required to provide clients with a well-considered and well-designed fire protection system for their operations – be it conveyor belts, transformers, hydraulic packs, water reticulation, fire pump stations or other specialised fire risk applications.

| Tel: | +27 12 665 0317 |

| Email: | [email protected] |

| www: | www.spero.co.za |

| Articles: | More information and articles about Spero Sensors & Instruments |

© Technews Publishing (Pty) Ltd. | All Rights Reserved.