How does one choose between an active RFID system that uses Wi-Fi over one that uses Zigbee or Bluetooth? Or is so-called 'conventional' active RFID (where small transmitter tags communicate with readers using highly optimised but non-standardised data formats) the better option? Which radio frequency is the most appropriate for the tags to transmit on? How accurately should the system locate an asset? How much and what type of data must the tag transmit?

This White Paper examines the options and choices available today and shows how active RFID solutions can deliver sustainable ROI and meet customer demands without requiring excessively expensive or complex technologies.

Executive summary

Sales of active RFID systems grew to $0,74 billion in 2007 and are projected to grow to $7,07 billion by 2017. The primary contributor to this growth is the need for realtime location systems (RTLS). Other contributors to the growth of active RFID technology are:

* Requirement for total asset visibility for assets or goods as they move through the supply chain. There is an increasing need for more visibility and more data about those assets and their condition as they're moving through production facilities, between sites, between carriers and in commercial buildings.

* Strong market demand for asset and people tracking. Factors driving this demand are safety and security, competitive cost reduction, and customer service requirements. Specifically, more emphasis has been placed on visibility due to the threat of terrorism and local epidemics or global pandemics. Active RFID is used in markets such as healthcare, commercial and industrial corporations for access control and tracking of valuable or critical assets.

* As the demand for active RFID technology expands across a wide range of vertical markets, the cost of the tags and systems has been reduced over the last several years.

* Active RFID technology is ideal for tracking of high-value items and repeated use in supply cycles. The low-consumption power requirement extends the battery life of active RFID technology up to seven years which in turn dramatically reduces the total cost of ownership.

* Development of ubiquitous sensor network environments where large quantities of active RFID tags with sensors are networked in commercial establishments, distribution centres and in healthcare facilities providing realtime data of asset conditions and status.

The amount of commercial interest stems from the growing need for organisations to track and trace their high value assets in realtime. There is a compelling reason behind this interest: 48% of enterprises mobile asset operations consume 5% or more of corporate revenue. Understanding where one's assets are and, in some cases, what their condition is can unlock cost savings that enable an RTLS system to deliver a return on the original investment in one to two years.

The executive who must analyse and decide on the best RTLS solution to employ has an unenviable job. Currently there are approximately 100 vendors to choose from, each promising that they offer the leading solution. The choice can become more confusing when attempting to gain an understanding of the technology underpinning the available RTLS solutions: radio frequency identification (RFID).

Active RFID is generally considered the best technology for RTLS applications due to the long tag detection range offered and ability for the tags to transmit on their own accord on a regular basis. RTLS systems typically triangulate a tag's position when three or more readers pick up the tag signal or will indicate a tag as being in a particular zone depending on which reader(s) detect it.

However, does one choose an active RFID system that uses Wi-Fi over one that uses Zigbee or Bluetooth? Or is so-called 'conventional' active RFID (where small transmitter tags communicate with readers using highly optimised but non-standardised data formats) the better option? Which radio frequency is the most appropriate for the tags to transmit on? How accurately should the system locate an asset? How much and what type of data must the tag transmit?

Understandably, the choices can be confusing and no simple answer exists. Yet thousands of companies from SMEs to multinationals and government organisations worldwide are today successfully using active RFID to track and manage their assets, improve their usage and control, improve their security, automate their processes and increase their productivity.

Considerations for an RTLS System

Before committing to any particular system, the decision-maker must evaluate a number of important considerations. Doing this will enable a true calculation of the total cost of ownership and the ability to then recoup the investment as quickly as possible through choosing the most appropriate RTLS system.

1. Why is there a need for an RTLS system?

While the concept of knowing where all the organisation's assets are right now, together with the added benefits this knowledge brings, is an enticing one, the ROI will be maximised in the shortest possible time if the RTLS system addresses specific needs within the business and the correct auto-identification technologies are employed. Reducing shrinkage, locating critical equipment quickly, utilising assets to the fullest, identifying attempts to remove or tamper with assets, or automating labour intensive systems are all valid reasons for implementing RTLS systems provided the cost saving over the life of the RTLS system is greater than the total cost of owning it.

2. What will be tracked and what will the benefits be?

In an ideal world an RTLS system would use an active RFID tag which is very small and flat in size, that works consistently irrespective of environment and orientation, while offering a very long battery lifespan, and costing just a few cents. In reality, until electronic and battery technology progresses significantly, active RFID tags will be relatively large, expensive and only suitable for use with assets that can accommodate them.

When evaluating the technology platform used by the RTLS system, it is useful to answer these questions:

* Does the vendor offer a range of tags that have the right shapes and sizes to be attached to the asset?

* Will the tag(s) survive the environmental conditions its assigned asset will be routinely exposed to?

* Do the tags conform to safety standards demanded by the environment? Intrinsic safety certification may be required and the components and materials used in their construction must conform to all applicable health and safety standards.

Active RFID tags emit radio signals and thus must conform to the relevant ETSI, FCC and/or national standards applicable in the country of deployment. The relevant certificates of legal conformance, human safety (Specific Absorption Rate or SAR certification) or test reports proving non-interference with sensitive electronic equipment should be readily available.

Likewise, some vendors' readers/interrogators will emit radio signals and these too must conform to all relevant standards and safety certifications.

No vendor may be able to offer tags that conform to all your requirements so their ability and willingness to customise the tags to suit the environmental, legal, safety and industry specific requirements is another consideration.

A true, comprehensive asset tracking system will very likely have to incorporate multiple auto-identification technologies, from bar codes to passive RFID and active RFID to offer a truly comprehensive solution. The software solution that controls and manages the RTLS system should be able to accommodate other auto-ID technologies so that the unique benefits of each can be utilised.

3. How accurately must assets be located?

If you merely need to know that an item is on site, then employing an expensive system to tell where precisely it is on site is a waste of money and will reduce the ROI achievable. Consider carefully how accurately assets must be located to achieve the business objectives and then select the RTLS system that provides that level of accuracy. It is commonly assumed that an RTLS system must provide tag location data in two or three dimensions, usually by means of triangulating a tag's position using multiple readers (see the panel alongside for an explanation on how this is done). Much is made of the accuracy of one system over another, but while knowing an asset's location to within a few centimetres sounds impressive, does the business case truly warrant that level of detail?

A very cost effective alternative to triangulation is the use of 'zones' in RTLS systems to locate assets. A zone can be defined by logically grouping one or more readers together in the software and it can be as small as a single room or it can cover an entire site. The system will not identify specifically where in the zone the asset is, but merely that it is in there. 'Zonal' RTLS systems do not require a dense network of readers or WiFi access points with overlapping read ranges as triangulation RTLS systems do, thus significantly reducing the infrastructure costs.

4. Where will the system be installed?

The environment that an RTLS system is installed in plays a crucial role in determining how the system's infrastructure must be installed and configured to meet the operational requirements demanded of it. In some cases, it may not be physically possible to achieve the required level of performance; such is the nature of radio signals.

Different radio frequencies have different properties and characteristics. No one frequency will ever be ideal for all the myriad of applications for RFID so the choice of hardware vendor will have to include analysis of the frequencies they operate on. For RTLS applications the frequencies most commonly available are 433, 868 and 915 MHz (Conventional active RFID), 2,45 GHz (Wi-Fi RFID) and 1-10 GHz (Ultra Wide Band RFID). Lower frequencies such as 433 MHz operate very well in crowded environments where objects and people interfere with the direct line of sight between the tag and reader, offering long range if required. Higher frequencies, such as 2,45 GHz and higher, offer higher data transmission speeds but transmit in narrower beams, making them ideal for data intensive tag transmissions and more precise determination of the incoming signal's direction, but far more susceptible to interference by objects in the environment, particularly where things and people move around - offices, hospitals, warehouses, container yards, etc.

Another important consideration is the level of competing signals at the frequency used by the RTLS system's hardware. The more devices there are using the same band, the greater the chance of data loss through transmission collisions and corruptions. Restrictions imposed by ETSI and FCC mean that active RFID tags cannot emit strong signals and could be drowned out by high levels of 'environmental noise' caused by competing signals or other systems.

5. How many tagged items will there be?

The more tagged items there are in any one area, the greater the number of transmissions that will be emitted per second. These transmissions also add to the 'noise' levels in the environment, and can interfere or 'collide' with each other. All major RFID vendors implement anti-collision methods to reduce the chances and effect of these collisions but there are limits to the number of tag messages that can get through to a reader in any one second.

Again the transmission capabilities and frequency used by the RFID hardware must be considered. For systems tagging thousands or tens of thousands of assets, it is crucial that the tag signals are kept as short as possible to enable regular transmissions as often as every second or else the transmit rate must be reduced to help preserve a useful battery life span. Where possible the tags should use a frequency least affected by other devices and the environment itself to minimise the effects of RF noise.

A tag that signals every few minutes or hours cannot truly provide the 'realtime' data that a true RTLS system demands. However, it is true that not all asset tracking or protection systems require 'realtime' data - an item in a warehouse or a painting on a wall may not move for weeks or months and the only time the tag must signal is when it does move. The integration of movement sensors into RFID tags can enable them to transmit infrequently when at rest, but rapidly when on the move, thus lengthening battery life but still ensuring rapid detection when changing location.

6. What will the true costs be?

Many persuasive cost saving arguments for each vendor exist: Wi-Fi tags offer the chance to use an existing Wi-Fi network access point infrastructure, thus apparently minimising infrastructure costs when compared to active RFID systems that require readers to be installed. However, conventional active RFID vendors offer tags that are as much as one fifth of the cost of Wi-Fi tags, with battery life spans up to three times longer than Wi-Fi tags.

The lifespan and transmit rate of the tags offered by the vendor of choice are important considerations when calculating the costs involved with an RTLS system. Apart from the upfront costs of attaching tags to assets, if the assets will need to be retagged, or tag batteries replaced, after a few years, the costs in hardware and manpower to achieve this must be considered as part of the total cost of ownership.

* How long must the tag last? Typically a 3-5 year life span satisfies most applications as most assets have a matching commercial or useful life span, however some assets such as vehicles or containers will have life spans exceeding 10 years. A system's total cost can significantly increase if assets must be re-tagged one or more times, or if the batteries in each of the deployed tags must be replaced.

* How 'realtime' must the RTLS or asset tracking system be? A tag that offers a suitable life span but only if it transmits once every few minutes is not going to offer a 'realtime' location system. RTLS systems used for security purposes will need a response to an unauthorised event within seconds, not minutes. Assets passing through a loading bay door have again just a second or two to register that they are leaving the warehouse and being loaded onto a specific vehicle. The options for reading tags in realtime, particularly those that can move at speed past the reader, require either beacon tags which transmit repeatedly from sub 1 second up to 2 second intervals or receive and respond to a 'wake-up' signal from the reader within milliseconds. This returns to the question above - what is the cost impact of the inevitably reduced battery life spans if the tag must transmit its data with rapid repetitions?

By properly evaluating all the questions above, it will be easier to answer the most important question: Who offers the best solution?

The choices available

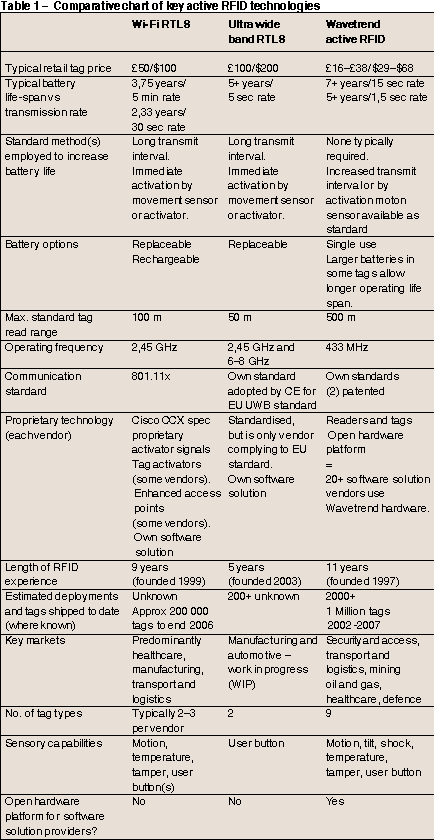

The various vendors of active RFID technology provide hardware and solutions based on three main types of active RFID technology:

1. Conventional Active RFID (300-915 MHz/UHF band)

The majority of active RFID systems deployed to date make use of a transmitting device (tag or beacon) to send a unique ID number to a receiver or network of receivers. The most commonly used frequencies are 433 MHz, 868 MHz (Europe) and 915 MHz (USA). 433 MHz is the most common freely available and unlicensed UHF frequency worldwide so many key vendors have standardised on it. Most vendors use their own proprietary protocols for transmitting the tag data thus being able to minimise the data transmission length and so maximise the tag battery lifespan. The functionality and operation of the hardware differs between vendors, with the maximum detection ranges offered being stated from 100 m to over 1 km. Conventional active RFID tags generally perform with exceptional battery life expectancies and lower costs than the other types of active RFID technology listed below, and have had the broadest deployment across all market sectors worldwide.

2. Wi-Fi RFID (2,45 GHz)

In recent years, as Wi-Fi networks have become ubiquitous, some vendors have provided tags that work with the IEEE 802.11x standard. The key advantages are seen as being the ability to use existing Wi-Fi infrastructure to implement RTLS systems based on Wi-Fi tag technology, and the argument that Wi-Fi RFID is a 'standardised technology'. Disadvantages include reduced tag lifespan due to the increased data overhead of using the 802.11x protocol and resultant increase in power consumption, the lack of uniform usage at the 802.11x standard by vendors and the use of proprietary tag activation systems, all in effect making each Wi-Fi vendor's hardware as proprietary as any conventional Active RFID vendor. Wi-Fi active RFID offers a maximum range of around 100 m.

3. Ultra Wide Band or UWB RFID (uses broad band of frequencies in the microwave band)

With the release of a broad spectrum of microwave frequencies by the FCC in 2003, UWB technology is now available for deployment with RTLS systems. The key advantage of UWB is the very precise locating of a tag within a three dimensional space. The key disadvantage of UWB is the very high cost of the infrastructure as compared against all other types of active RFID technology. UWB offers a maximum range of around 50 m.

In addition to the three main technology types listed above, other technology options are emerging in the active RFID arena, such as Zigbee (IEEE 802.15.4), Bluetooth and GPS.

* Zigbee offers low power, bi-directional data communications via a mesh network, with range up to around 70 m and thus can be employed in areas where traditional active RFID is used, but is not ideal for identifying location nor is it widely available as yet. The Zigbee standards for RFID are still not fully developed.

* Bluetooth, the short-range wireless networking standard most commonly found in mobile phones and computer accessories, is also looked towards for providing a platform for asset tracking applications. Its shorter range (approx. 10 m), slower data transmission rate than Wi-Fi and very high power consumption mean that it might only be suitable for niche applications where long range and battery life spans of days or less are not critical factors.

* GPS is already widely employed for vehicle fleet and shipping container tracking. Its relatively high-cost, high power consumption and difficulties with working indoors make it unsuitable for the large majority of asset tracking and monitoring applications.

In evaluating technologies for implementation, it is important to consider all factors in making a final decision. Analysis factors should include:

* Expected lifetime of tag versus asset lifetime and any further costs associated with retagging assets in future.

* Weighing the advantages each vendor's RTLS solution offers against the business problem at hand to determine which technology and software solution is the best to meet the needs of the project.

* Consider whether Wi-Fi RTLS triangulation will need additional access points of activators, which will add extra cost to implementation.

* Comparison of all product attributes for consideration: battery life span, tag detection range, and selection of different tag shapes and capabilities available to attach to meet the tracking requirements of the assets in the specific application.

Standards in active RFID

There have been many references to proprietary technology in this paper. The truth of the matter is that in practical terms, every active RFID vendor is proprietary in one form or another. While standard communication protocols may be employed for transmitting data (802.11x, GSM/GPRS, ISO 18000-7433 MHz et al), the data structure may not be standardised, vendor proprietary hardware may be required to ensure the system functions as required, the vendor's own software solution may be the only one capable of working with the technology they provide, or the published standard may be proprietary to one vendor, requiring other vendors to potentially pay up to millions of pounds for the right to produce only certain products using the standard, restricting the number of vendors offering the standardised technology.

Conclusion

New standards will continue to emerge over time, and eventually multiple open standards, tailored in terms of frequency, data structure and communication protocols will appear, making it easier to understand the myriad of options in active RFID.

A truly open active RFID standard would at minimum allow any vendor's tag to work with any vendor's reader on any vendor's RTLS software package seamlessly. Each future standard will almost certainly be aimed at specific market verticals or specific applications, by combining the best RF frequency, protocol and data structure for that application or vertical. The need to evaluate each standardised system's benefits against the business need will not be removed. New, improved technology will continue to be developed thus forcing the further development of standards. Proprietary active RFID technology designed to cater to very specific or niche requirements will continue to exist.

In the meantime, the decision about which active RFID vendor to use to meet the immediate RTLS requirements that any company or organisation has today will have to be made by asking the critical questions posed in this paper and careful evaluation of each vendor's technology, software solution, deployment experience and user case history.

An example of the limitations of what can be tagged with active RFID tags:

There is intense interest in tracking surgical instruments to provide full audit trails of usage and to reduce errors during operations, but no active RFID tag in existence today can be truly used to track such small items. A passive RFID tag could fit, but cannot endure the high temperature sterilisation processes used on it.

Hospitals thus have to consider using 2D barcode technology and this can be etched onto the instrument and be unaffected by the sterilisation process.

Most major RTLS system providers (also known as middleware providers), such as IBM, are vendor agnostic and can support multiple auto-ID technologies. Most active RFID vendors provide their own RTLS applications that are restricted to working with their hardware only.

How triangulation works: When a tag emits a signal, three or four readers detect it. They measure either the time it has taken for the tag to respond to a request to transmit or they measure the strength of the incoming signal (weaker signals or longer response times indicate greater distance between the tag and reader). Software with complex algorithms analyses the data from each reader and uses the response time or signal strength or both if available to determine how far the tag is from each reader and to then determine the exact position of the tag between them. The accuracy of this method is affected by numerous factors, including shielding of the signal by objects or people in the environment, sufficient readers to provide total coverage, orientation of the tag relative to the reader’s antenna and the quality of the software algorithms employed.

© Technews Publishing (Pty) Ltd. | All Rights Reserved.